Utility pole testing and utility pole inspections play a crucial role in ensuring the safety and reliability of our electrical and communication infrastructure. These processes may not be in the spotlight, but they are essential for maintaining the integrity of utility poles, preventing accidents, and ensuring uninterrupted service. In this comprehensive guide, we’ll dive deep into the world of utility pole testing and utility pole inspections, covering everything from their significance to the frequently asked questions about them.

Introduction

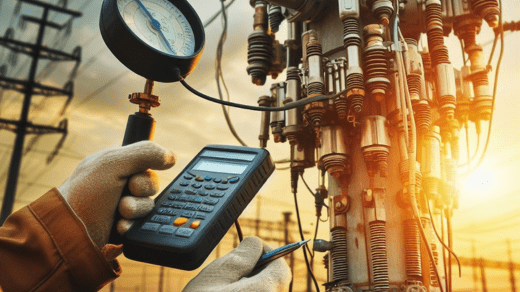

Utility poles are a common sight in our neighborhoods, silently supporting overhead power lines, telephone cables, and internet connections. They perform this vital function day in and day out, but how do we ensure that they continue to do so safely and reliably? The answer lies in utility pole testing and utility pole inspections.

Utility Pole Testing, Utility Pole Inspections: What Are They?

Utility pole testing and utility pole inspections are systematic processes designed to assess the condition of utility poles and identify potential issues. These evaluations are critical for maintaining the infrastructure’s safety and longevity. Utility companies, telecom providers, and municipalities all rely on these procedures to prevent accidents, reduce downtime, and ensure uninterrupted services.

The Importance of Utility Pole Testing and Utility Pole Inspections

- Safety First

Utility poles carry high-voltage electrical lines and heavy communication cables. Ensuring their structural integrity is paramount to prevent accidents that could endanger lives and property. Regular inspections and testing help identify weak or damaged poles that need immediate attention.

- Reliability

Utility poles are the backbone of our electrical and communication systems. A failure in any single pole can lead to service disruptions affecting thousands of customers. By proactively testing and inspecting utility poles, service providers can identify and replace deteriorating poles before they fail.

- Cost Savings

Routine inspections and testing can identify issues early, reducing the cost of emergency repairs and minimizing service interruptions. This proactive approach not only saves money but also ensures that services remain uninterrupted.

Utility Pole Testing: Methods and Techniques

Utility pole testing involves various methods and techniques to assess the condition of the poles accurately. Some of the commonly used methods include:

1. Visual Inspection

Visual inspections involve a thorough examination of the utility pole’s exterior, looking for visible signs of damage, decay, or wear. This is often the first step in identifying potential issues.

2. Ground Line Inspection

Inspecting the portion of the pole that’s underground is crucial, as this area is most susceptible to decay and moisture-related damage. Ground line inspections use specialized tools to assess the condition of this critical area.

3. Load Testing

Load testing involves applying controlled forces to the utility pole to determine its load-bearing capacity. This helps identify weak poles that may need replacement.

4. Pole-Top Inspections

Climbing to the top of the pole allows inspectors to assess the condition of crossarms, pins, and other hardware. Any issues found at this level can be addressed promptly.

Utility Pole Inspections: Frequency and Guidelines

Utility pole inspections should be conducted regularly to ensure the safety and reliability of the infrastructure. The frequency of inspections may vary depending on several factors, including the pole’s age, location, and environmental conditions.

In the United States, guidelines and regulations are in place to ensure that utilityassetmanagement.com/utility-pole-inspections/ are performed according to industry standards. These regulations help maintain a consistent level of safety and reliability across the country.

Utility pole testing and utility pole inspections are essential for maintaining the safety and reliability of our electrical and communication infrastructure. These processes ensure that utility poles can withstand the test of time and continue to serve our communities without interruptions. By understanding their significance and adhering to industry guidelines, we can ensure a brighter and more connected future.