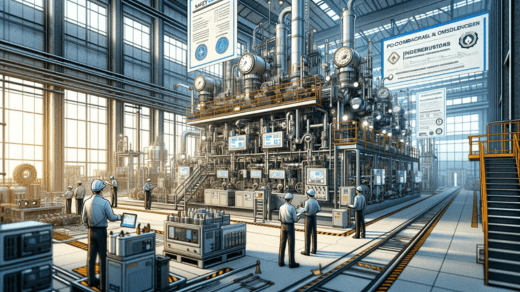

In the industrial scenario, prioritising workplace safety and adhering to regulatory standards are paramount. One often overlooked aspect of ensuring security and compliance is reliable industrial connectors. Electrical connectors are essential in many industrial applications, providing efficient and safe electrical connections that contribute significantly to overall safety protocols.

1. The Role Of Industrial Connectors In Safety

Industrial connectors aim to withstand the demanding environment of industrial settings, where electrical connections are subject to harsh conditions such as moisture, vibration, and temperature fluctuations. By using high-quality connectors, businesses can reduce the risk of electrical failures and hazards, increasing workplace safety.

2. Ensuring Regulatory Compliance

Regulatory bodies mandate strict guidelines for electrical systems in industrial environments to prevent accidents and ensure worker safety. It is necessary to use conforming industrial connectors. These connectors aim and tested to conform to industry-specific regulations, giving businesses peace of mind regarding compliance.

3. Benefits Of Using Reliable Industrial Connectors

- Durability And Reliability: These connectors aim to last, providing durability and resilience against wear and tear. This reliability results in fewer breakdowns and maintenance issues, reducing downtime and associated risks.

- Advanced Safety Features: Advanced connectors aim for safety features like locking mechanisms and insulation properties that reduce the risk of electrical faults, short circuits, and fire.

- Ease Of Installation And Maintenance: Modern connectors are designed for easy installation and maintenance, allowing technicians to quickly and safely manage electrical connections without extensive downtime.

- High Performance in Harsh Environments: These adapters aim to deliver reliable performance in environments. They can endure extreme temperatures and vibrations without compromising performance. This flexibility ensures continuous operation even in challenging conditions, making them ideal for manufacturing, oil and gas, and transportation.

- Advanced Security And Tamper Resistance: Many connectors aim for security features that prevent unauthorised access or tampering. It is critical in industries where maintaining the integrity and security of electrical connections is paramount, such as military applications or sensitive industrial installations.

- Modularity And Scalability: Modern adapters often come with modular designs, allowing easy customisation and scalability of electrical systems.

4. Choosing The Right Industrial Connectors

When selecting industrial connectors, the environment’s requirements must be considered. Factors such as voltage requirements, environmental conditions, and regulatory standards should guide the choice of connectors. Consulting with experienced connector manufacturers ensures businesses receive connectors tailored to their needs.

5. Connectors Manufacturers In India

Connector manufacturers in India are leading providers of high-quality industrial connectors. Committed to innovation and safety, connector manufacturers like Allied Connectors offer diverse connectors designed to meet stringent industry standards and ensure optimal performance in demanding environments.

6. Innovations In Industrial Connectivity

Industrial connectivity is constantly evolving due to advances in materials and technology. The new connectors boast improved efficiency, lower maintenance requirements, and advanced safety features, underscoring their importance in workplace safety and regulatory compliance.