Discover how T type thermocouples can enhance your industrial machinery performance. Learn about their benefits and applications in our latest article!

In the realm of industrial machinery, precision and accuracy play a pivotal role in ensuring optimal performance. One key component that significantly influences the smooth operation of these machines is the T type thermocouple. But, what is a T type thermocouple, and how can it enhance your equipment? Let’s delve into the details.

Understanding T Type Thermocouples: A Detailed Overview

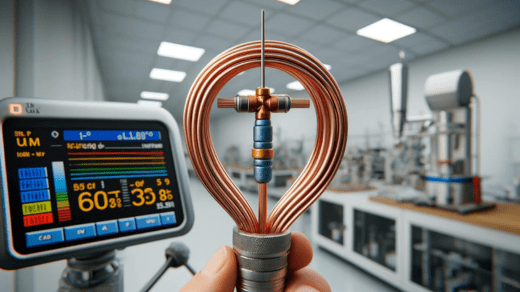

T type thermocouples are temperature sensors commonly utilized in industrial settings due to their reliability and accuracy. These thermocouples are crafted from two distinct alloys – copper and constantan – which generate a voltage proportional to the temperature variance between the hot and cold junctions. This voltage is then converted into a temperature reading, providing essential data for process monitoring and control.

Operating Principle of T Type Thermocouples

T type thermocouples operate on the Seebeck effect, where a temperature gradient between two dissimilar metals generates an electromotive force (EMF). This EMF is directly linked to the temperature difference, enabling precise temperature measurements across a wide range.

Benefits of T Type Thermocouples

A significant advantage of type T thermocouples is their high sensitivity and accuracy in measuring temperatures from -200°C to 350°C. This makes them ideal for applications requiring precise temperature control, such as in chemical processing, pharmaceutical manufacturing, and food production.

The Significance of Type T Thermocouples in Industrial Machinery

T type thermocouples play a crucial role in ensuring the safety and efficiency of industrial machinery. By providing real-time temperature data, they aid in preventing overheating, optimizing processes, and preserving product quality. Whether monitoring furnace, reactor, or storage tank temperatures, T type thermocouples are essential in various industrial applications.

Enhancing Safety and Reliability

Due to their ability to withstand high temperatures and harsh conditions, T type thermocouples contribute to the safe operation of industrial equipment. By alerting operators to temperature fluctuations and potential issues, they help prevent costly breakdowns and ensure the longevity of machinery.

Improving Product Quality

In industries where precise temperature control is critical for product quality, T type thermocouples play a pivotal role. By maintaining consistent temperatures during manufacturing processes, they assist in producing high-quality products that meet stringent standards and regulations.

Choosing the Right T Type Thermocouple for Your Equipment

Selecting the appropriate T type thermocouple for your industrial machinery is essential for accurate temperature measurements and optimal performance. Consider the following factors when choosing a T type thermocouple:

Temperature Range

Ensure the thermocouple you choose can operate within the temperatures present in your application without compromising accuracy or longevity.

Environment

Consider the environmental conditions where the thermocouple will be placed. Choose a thermocouple with the right sheath material and insulation to withstand corrosive chemicals, high humidity, or mechanical stress.

Response Time

Select a thermocouple with a fast response time for applications with rapid temperature fluctuations to maintain control and accuracy.Consideration Description Temperature Range Ensure the thermocouple operates within the required temperature range for accurate readings and longevity. Environment Select a thermocouple with suitable sheath material and insulation to withstand environmental factors like humidity or chemical exposure. Response Time Opt for a thermocouple with a fast response time for applications with rapid temperature changes to maintain control and accuracy. Location Placement Position the thermocouple probe at the critical point in the equipment for accurate monitoring, avoiding factors that could impact readings. Calibration Regularly calibrate the thermocouple using a certified source to verify readings and ensure accuracy over time. Insulation Use high-quality insulation to protect leads from electrical interference, ensuring accurate temperature measurements.

Maximizing T Type Thermocouple Performance through Installation

Proper installation of T type thermocouples is crucial for accurate temperature measurements and reliable performance. Follow these tips to enhance the effectiveness of your thermocouples:

Location Placement

Position the thermocouple probe at the most critical point in your equipment where temperature monitoring is crucial. Avoid areas with excessive vibration, direct sunlight, or airflow that could impact the accuracy of readings.

Calibration

Regularly calibrate T type thermocouples using a certified source to verify readings and maintain accuracy over time.

Insulation

Use high-quality insulating materials to protect the thermocouple leads from electrical interference and ensure accurate temperature readings.

Troubleshooting Common T Type Thermocouple Issues

Although T type thermocouples are reliable sensors, they can encounter problems affecting their performance. Common issues include drift in temperature readings, signal interference, and physical damage. Here are some troubleshooting tips:

Drift in Temperature Readings

Recalibrate the thermocouple to correct any offset errors causing temperature reading shifts over time. Check for loose connections or damaged leads contributing to the drift.

Signal Interference

Shield thermocouple leads from electromagnetic interference by relocating the sensor to a quieter environment or using shielding methods to minimize signal disruption.

Physical Damage

Inspect the thermocouple for damage like cracks or corrosion. Replace any damaged components to prevent further issues and maintain accurate temperature measurements.

Enhancing Efficiency and Accuracy with T Type Thermocouples

By utilizing the capabilities of T type thermocouples, industrial facilities can improve efficiency, product quality, and operational safety. Incorporating features like digital interfaces, wireless connectivity, and data logging can further optimize T type thermocouple performance.

Remote Monitoring

Integrating T type thermocouples with remote monitoring systems enables operators to track temperature trends, receive critical condition alerts, and make real-time decisions. This proactive approach minimizes downtime and enhances productivity.

Data Analysis

Leveraging temperature data collected by T type thermocouples for analytics and predictive maintenance helps identify patterns, optimize processes, and prevent failures. Analyzing trends enables data-driven decisions to enhance efficiency and reliability.

Future Trends in T Type Thermocouple Technology for Industrial Applications

As technology progresses, the future of T type thermocouples in industrial applications appears promising. Emerging trends include artificial intelligence integration for predictive analytics, self-diagnostic capabilities, and IoT connectivity for seamless integration with smart systems.

Artificial Intelligence Integration

Artificial intelligence enables T type thermocouples to predict failures, optimize temperature control processes, and extend equipment lifespan. This predictive maintenance approach enhances operational efficiency and reduces downtime.

Self-Diagnostic Capabilities

Future T type thermocouples may feature self-diagnostic functions to monitor performance, detect anomalies, and alert operators to potential issues. This proactive maintenance approach streamlines troubleshooting and enhances temperature measurement reliability.

IoT Connectivity

IoT connectivity in T type thermocouples enables real-time data transmission, remote monitoring, and cloud-based analytics for seamless integration with industrial automation systems. This connectivity revolutionizes temperature control and monitoring in industrial settings.

In conclusion, T type thermocouples are essential tools for ensuring the efficiency, accuracy, and safety of industrial machinery. Understanding their principles, selecting the right thermocouple, and following best practices for installation and maintenance can elevate equipment performance and productivity in your facility. Stay informed about the latest advancements in T type thermocouple technology for innovative industrial temperature sensing solutions.